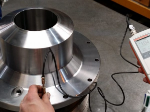

Ferritscope Test

The main cause of hot cracking; They are metallic compounds with low melting temperature, which are formed by elements such as sulfur and phosphorus and have a high tendency to aggregate at grain boundaries. If these compounds are located in the weld seam or in the heat affected zone, they spread towards the grain boundaries and cause cracking as the weld cools and tensile stresses occur.

It is recommended that the amount of ferrite in the structure be at least 4% in order to be resistant to the risk of hot cracking. The presence of ferritin is determined by magnetic measuring instruments calibrated according to AWS A.4.2.

The aim is to determine the amount of ferrite (iron) in a non-destructive, sensitive and accurate manner, in production, delivery or in the laboratory, according to the magnetic induction method.

APPLICATION AREA

Measurement of the amount of ferrite

Austenitic steel welds (like tubes)

Normal construction steels with austenitic chromium alloy (such as boilers, ship industry.)

Duplex steels.